| Usage: | Used for construction field, low pressure liquid transportation, in various engineering purposes, fencing, scaffolding etc. |

| SAW: | Submerged arc welded pipe |

| LSAW: | Longitudinal submerged arc welding pipe |

| SAWL: | Submerged arc welded longitudinal pipe |

| Standard: | API 5L, ASTM A500, ASTM A252, ASTM 53, EN10219, EN10210,ASTMA572 GR.50 AS1163, JIS G3452, BS1387 |

| Certificate: | ISO 9001, ISO 14001, OHSAS 18001, API 5L PSL1&PSL2, CE (CPR ), GOST Certificates |

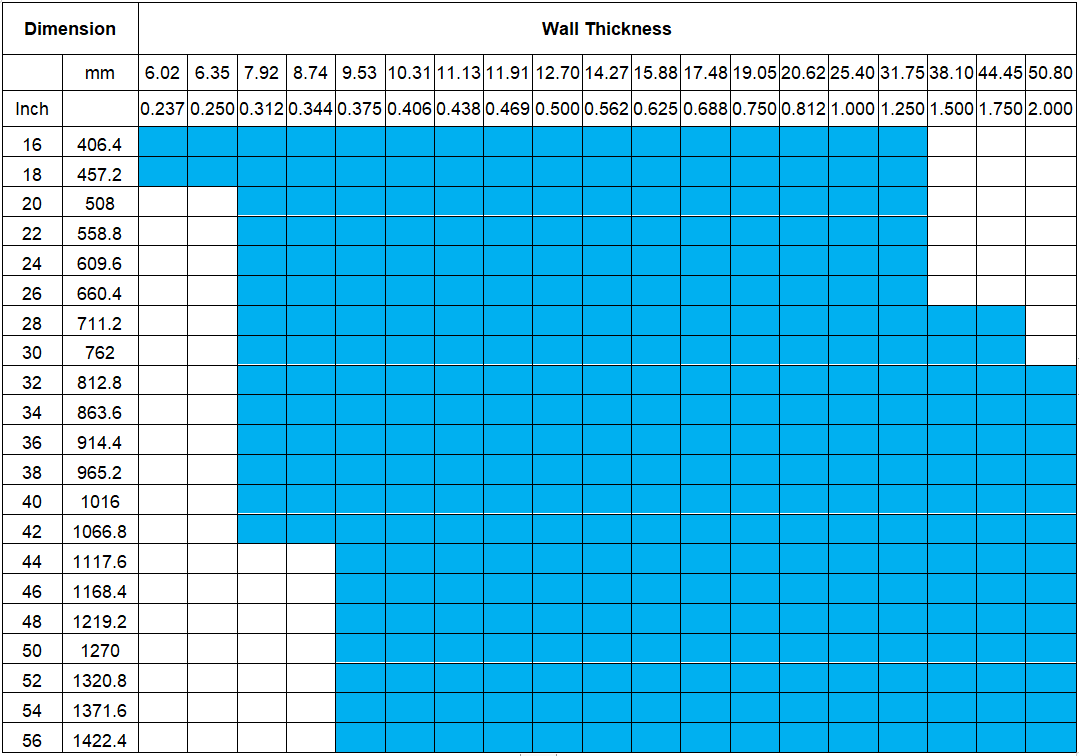

| Out Diameter: | 406.4mm - 1422.4mm (16"-56") |

| Wall Thk: | 9.53mm-50mm |

| Length: | 6M-12.5M |

| Steel Grade: | API 5L PSL 1 & PSL2: GR B, X42, X46, X56, X60, X65, X70 ASTM A53: GR.A, GR.B EN10219/EN10210: S275, S275JR, S355JRH, S355J2H GB/T3091: Q195, Q215, Q235, Q355, L175, L210, L245, L320, L360- L555 AS1163-2016:C250/C250L0 C350/C350L0 ASTM A572 GR.50 |

| Surface: | Fusion bond Epoxy coating, Coal Tar Epoxy, 3PE, Vanish Coating, Bitumen Coating, Black Oil coating as per customer’s requirement |

| Tests: | Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation), Technical Properties (DWT, Guided Bend Test, Impact Test), Exterior Size Inspection, Hydrostatic Test, RT (X-Ray Test) |

| MTC: | EN 10204/3.1B, EN 10204/3.2 (with Third Party Inspection) |